Since its inception in 2006, Happy Family Organics has been on a mission to “change the trajectory of children’s health through nutrition.”

Even as the company has grown, it continues to offer smartly packaged organic food options grown without artificial hormones, GMOs or toxic persistent pesticides.

Happy Family has also deepened their commitment to sustainability. Of the six climate commitments they’ve made though the Climate Collaborative, packaging is a core priority.

PROPOSED PACKAGING ADJUSTMENTS

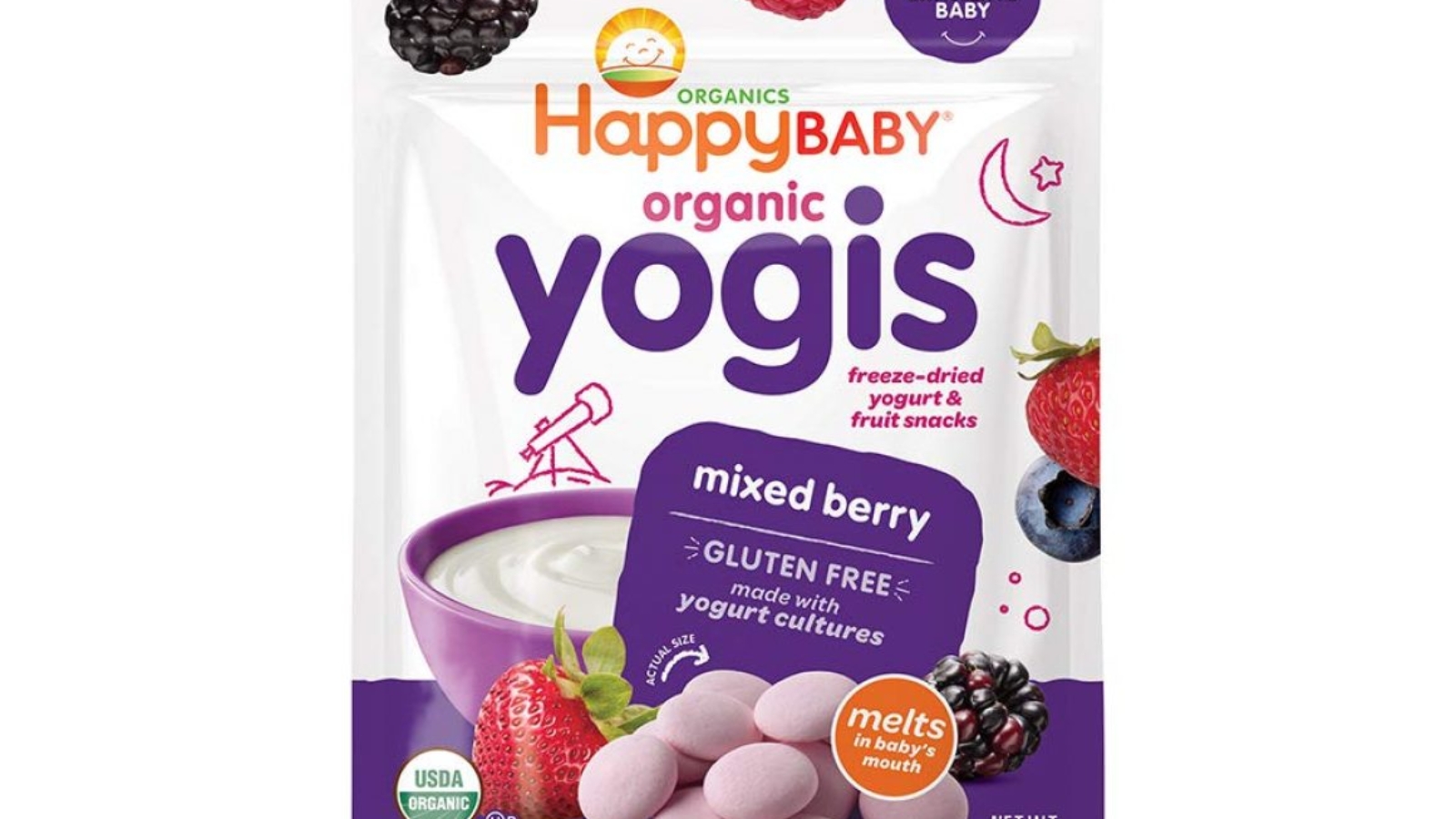

Among the packaged products ripe for revamping: Happy Baby Organic Yogis, a popular freeze-dried yogurt and fruit snack, which was bigger and bulkier than necessary.

Working with their supplier, Happy Family Organics Packaging Development Manager Marcu Alexander and Director of Sustainability Katie Clark reduced the height of the pouch and adjusted the size of the outer case while still protecting the product.

UNDERSTANDING THE BIG PICTURE

The company knew that assessing progress in packaging and looking at the full life cycle of packaging emissions was crucial to getting a full picture of their products’ carbon footprints.

Happy Family Organics was already working to deepen their industry engagement and improve packaging through a partnership with the Climate Collaborative (CC). They were able to amplify their efforts by partnering with Trayak, which specializes in helping companies quickly benchmark their existing packaging and use that data to improve the sustainability of their packaging.

The three organizations worked together to collect the Yogis packaging system information (materials, masses, conversion processes, etc.) and performed a Life Cycle Assessment (LCA) with Trayak’s EcoImpact-COMPASS (Comparative Packaging Assessment) tool.

THE RESULT: POSITIVE IMPACT ON ALL PHASES OF THE LIFE CYCLE

The collaboration on the new design for Happy Baby Organic Yogis had a net positive impact on all phases of the life cycle of the product from an emissions standpoint, but also from an overall product efficiency and cost perspective.

GREENHOUSE GAS REDUCTIONS

- 13% for material impact

- 14% reduction in end-of-life impacts (landfilling)

- 28% reduction in transportation impacts

With an annual production of almost 8 million Yogis products, Happy Family Organics is reducing GHG emissions by 188,368 kg CO2 eq — the equivalent of taking 40 passenger vehicles off the road for an entire year.

MATERIAL REDUCTIONS

Changes to the pouch and case resulted in significant reduction in materials used and pallets required for transport. This right-sized design annually saves:

- 8,640 lbs. of pouch materials (8% reduction)

- 197,534 lbs. of corrugated cardboard (14% reduction)

- 3,666 wooden pallets (145,969 lbs.) (40% reduction)

- 12 million fewer gallons of water consumption annually (13% reduction)

TRANSPORTATION REDUCTIONS

Happy Family Organics saw improvements in reduced material use, efficient transport and less material sent to landfill.

A pallet of original-sized Yogis transported only 864 bags, while the new right-sized packaging system transports 1,428 bags — a 65% improvement.

Additionally, the cardboard master cases were size reduced, allowing Happy Family Organics to fit more onto the pallet (4% increase).

COST SAVINGS AND THE BUSINESS CASE

Many companies cite poor performance or increased cost as significant barriers to making their packaging more sustainable. For Happy Family Organics, the new pouch offered increased barrier properties, which better preserve the product in hopes of reducing food waste.

The 37% cost savings that the company saw can be attributed to several factors:

- Using less material means paying for less material

- Lighter packages mean more can be shipped with the same amount of fuel, reducing truckloads and shipping costs

- The new materials were transported over shorter distances, also reducing shipping costs

CONSUMER PERCEPTION

There was a concern that sales would dip if consumers thought that the number of Yogis per package had decreased. Howeer, by being transparent with their consumer base, Happy Family Organics has earned praise for the new right-size package design.

Below are comments from consumers on a Facebook post about the Yogis packaging change:

“Good job! My daughter loves these … They’re going to be even better now that we’re reducing waste. I did think the packaging was too big before, almost like wasted space!”

“Fantastic to see this. We love our Happy Baby products, but I’ll be happy to cut back on waste.”

“Yes, I love this! Less waste is always a bonus in my house!”